AI Agents for Automotive Manufacturing

Predict failures, cut changeover losses, and improve first‑time quality across assembly, robotics, and paint with autonomous maintenance copilots.

Critical Assets

Where our agents make the biggest impact

Assembly Lines

Conveyors and stations orchestrated for takt; agents watch for bottlenecks and drift.

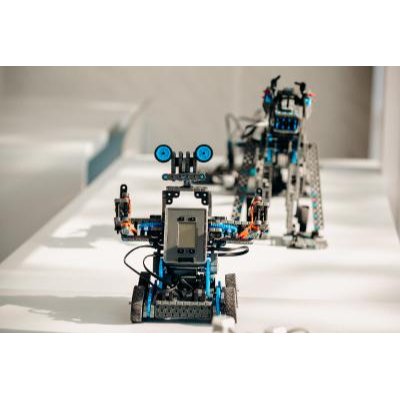

Robotic Systems

Welding/painting robots; agents track torque, paths, and calibration windows.

Stamping & Forming

Press health, die wear, lubrication anomalies flagged early.

Just‑in‑Time Schedules

No room for surprise downtime across takt-driven lines.

Complex Automation

Robots/PLCs require precise calibration and version control.

Model Changeovers

Frequent reconfiguration without extending downtime.

What Our AI Agents Do

Predictive & Condition Monitoring

Detect bearing wear, vibration spikes, thermal anomalies, and lubrication issues; generate work orders with probable root causes.

- Robot joint torque and cycle drift alerts

- Press stroke/vibration envelope breaches

- Paint booth temp/RH window monitoring

JIT Maintenance & Changeover Assist

Schedule tasks into natural breaks; retrieve validated SOPs, and verify calibration post-changeover.

- Automatic windowing to takt buffers

- Digital checks for PLC/robot version parity

- One‑point lessons tied to recent issues